BIOFICIENT + 2 SEWAGE TREATMENT PLANT (10 POP)

Product Ref: 0006065

For a site visit or site assessment please click on link to form

Product Description

BIOFICIENT + 2 SEWAGE TREATMENT PLANT (10 POP)

The BioFicient + 2 Sewage Treatment Plant has been specially designed for shallow dig applications, allowing for an unobtrusive below ground installation. Its unique design features include its low profile and extension neck, saving on-site time and expense. The Bioficient + 2 Sewage Treatment Plant is a highly economical and reliable solution for your sewage treatment needs. With low running costs, the Bioficient + Sewage Treatment Plant is easy to maintain. For added peace of mind, we offer a warranty period of 3 years*. Terms and conditions apply – please visit Warranty Terms.

Features and benefits

- Suitable for population equivalent of 10

- Material: Plastic/ GRP

- Outlet Level :800 - 1,600mm

- Pipework Diameter :110mm

- Cover size 700mm dia

- Blower Rate - 95W

- Shallow dig

- Low energy consumption

- Monitor with control panel

- Easy to set up and operate

- Minimal visual impact - low profile covers

- Excellent ammonia reduction (0.4mg/l)

- Installation in trafficked areas (structural design advice required by others)

- Saving on-site installation time

- EN 12566-3 tested and approved

- Fully CE marked in line with the CPR 2013

- Designed in compliance with the EPA Code of Practice

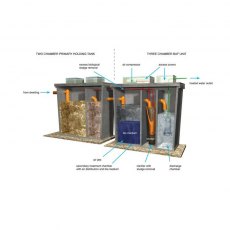

How the BioFicient + works

1) Wastewater and sewage flows into the primary settlement tank where solids are settled out and retained. Settled sewage is displaced from primary zone and enters the aerated media reactor (Biozone).

2) Solids are broken down by air agitated media in the Biozone. Media and liquid circulation in the Biozone is achieved through the use of a compressor and diffuser, which introduces fresh air into each compartment. The liquor is constantly recirculated and contacts the moving media and as it does so, it is purified by the micro organisms growing on the surface of the media and within the moving liquor. Excess growth of biomass is shed as solid particles into the liquor.

3) The final settlement tank is where fine solids form to sludge. At preset intervals, portions of the sludge and liquor are returned to the primary tank for additional treatment. The primary and final settlement zones should be emptied of sludge every 12 months.

4) Final effluent is discharged from the final settlement tank. With regulator approval, it is suitable for discharge to a watercourse or drainage field.

Performance and Compliance:

- BS EN 12566 Part 3 tested and approved

- Fully marked in line with the CPR 2013

Applications:

- Single / Multiple homes

- Barn conversions

- Small office developments

- Farms

- Stable yard toilet

- Offices/Light industrial premises

*DELIVERY TERMS

All tanks are delivered on 45ft Flat-bed Articulated Trailers, so off-loading equipment on site is necessary.

HIAB off-loading is available at extra cost, if requested.

It is the responsibility of the customer to inform us, if off-loading equipment is required.

WOULD YOU LIKE A SITE ASSESSMENT DONE?

WOULD YOU LIKE A SITE ASSESSMENT DONE?

Before you purchase your sewage treatment system you may need advice on which system is suitable. From percolation tests and site assessments to specifiying the correct sewage treatment plant for installation we can help you through the process. If you would like our help, please click on Site Assessment Report and fill out the form and we can take it from there.

Kingspan offer a commissioning and maintenance service on all their wastewater products. Your service and maintenance visit will include; system integrity and operation, check of all moving parts, effluent quality, flow rates, discharge consents and management system checks.

DO YOU REQUIRE COMMISSIONING?

To ensure your system operates to maximum efficiency, we recommend tried and tested commissioning by Klargesters own trained engineers.

Our unrivalled knowledge means that we are best placed to carry out bespoke assessments to get your system up and running. The commissioning will also provide you with a unique checklist against your system, ensuring your complete peace of mind and reassurance that your system's mechanical and electrical components are in good working order.

WHAT'S INCLUDED IN THE COMMISSIONING? CLICK HERE FOR MORE INFORMATION

For more information download the information below, call 0818 543 500 or go to Kingspan Service

Further sizes are available on request

Product Specification

- Product Code: KLA

- Fuel Type: Sewage

- Lid size: 700

- Shape: Underground

- Shipping: Customer Off Loading, Free Delivery

- Volume: 5585ltr

- Dimensions: L:3189mm

- Diameter: 2010mm

Delivery Terms

Kingspan Tanks - Tail-lift deliveries are available for most tanks up to 2,000 Litre capacities for kerbside delivery.

It is the responsibility of the customer to inform us, if off-loading equipment is required.

Klargester Tanks - All tanks are delivered on 45ft Flat-bed Articulated Trailers, so off-loading equipment on site is necessary.

HIAB off-loading is available at extra cost, if requested.

It is the responsibility of the customer to inform us, if off-loading equipment is required.

Harlequin Tanks - Tail-lift deliveries are available for most tanks up to 2,500 Litre capacities for kerbside delivery subject to availability.

It is the responsibility of the customer to inform us, if off-loading equipment is required.

tanks.ie undertakes to attempt to fulfill all orders within a maximum of 7 working days of order acceptance, unless advised otherwise. In the event that any order is delayed, tanks.ie will not be responsible for any consequential loss or damage that this delay may cause.

Smaller items (including most accessories and consumables) will normally be despatched by courier.

Larger items (including all storage tanks) will normally be delivered by carrier.

Please note that for all items delivered by carrier, normally a truck + 40ft trailer, it is the customer's responsibility to ensure adequate vehicular access and to provide suitable offloading equipment, where required. Please notify us, if this might pose a problem and we will endeavour to facilitate your request.

Returns Information

ORDER CANCELLATION

In accordance with Irish and European Union consumer laws, you have seven days after receipt of order to cancel the order in its entirety or any part thereof, providing the goods are in a re-saleable condition. Should you wish to cancel any order, you must first contact sales@tanks.ie for a ‘Returns Authorisation Number’.

Please call 051 351325 or e-mail sales@tanks.ie

After the Returns Authorisation Number has been issued, we will make arrangements with you for the goods to be returned. If you wish tanks.ie to arrange the collection of the goods, please note that a carriage and administration charge will apply, which will not exceed 35% of the gross value of the goods.

Upon return of the cancelled goods to tanks.ie and verification that they are in a re-saleable condition, we will refund the value of the goods, less any collection and administration charges, within 28 days.

DEFECTIVE PRODUCTS

If you believe that products you have purchased from tanks.ie are defective, please report this immediately to tanks.ie by e-mail sales@tanks.ie or call 051 351325.

If they are within the manufacturer’s guarantee period, we will arrange with the manufacturer to replace or repair the goods at the manufacturer’s discretion and consistent with their guarantee.

Where it is necessary to inspect the goods on site and an inspection proves the fault is neither the fault of tanks.ie, nor the product manufacturer, an inspection charge will apply, which will be advised by the manufacturer prior to site inspection.

Please note that where guarantees are available in excess of those required by law, these are provided at the discretion of the product manufacturer and not tanks.ie. Additionally, tanks.ie will not be liable for any claims for consequential damage or loss.