Featured Products

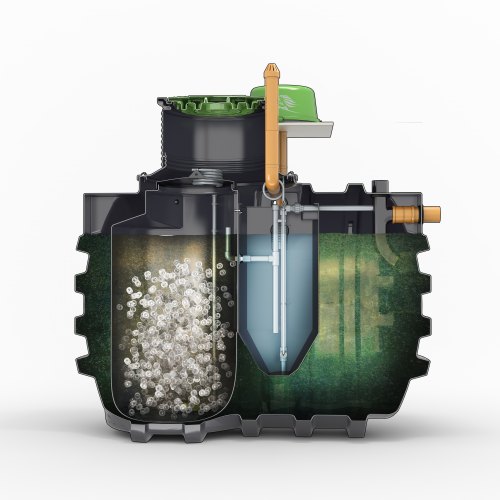

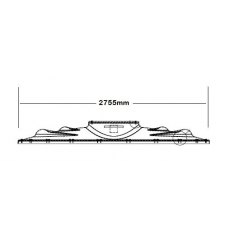

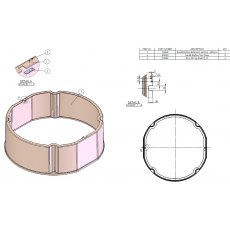

(€923.21 inc VAT)

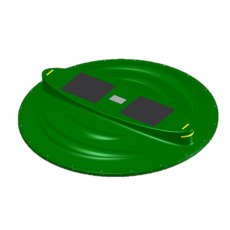

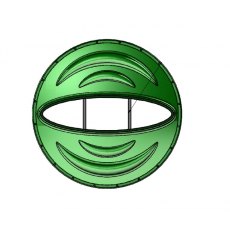

(€164.23 inc VAT)

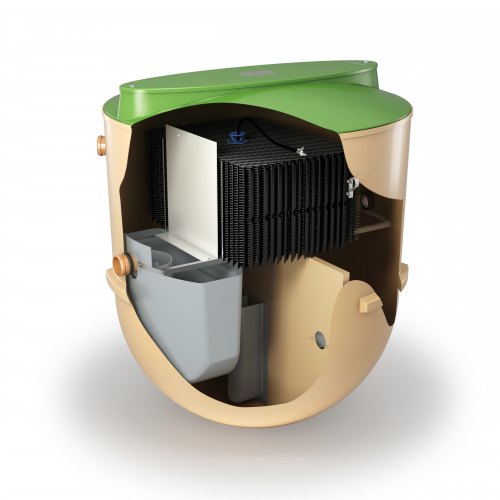

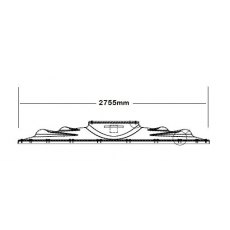

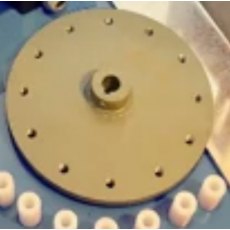

(€491.94 inc VAT)

Sewage Treatment Plant Accessories FAQs

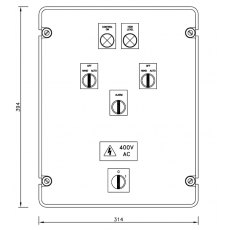

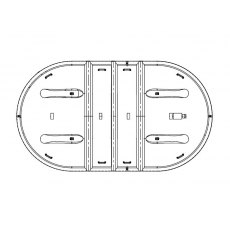

What is a distribution box on a septic tank?

A distribution box is used to divide the effluent flow from a septic tank into two or more percolation areas.

Is distribution box necessary?

The distribution box is a major part of the septic system being able to function properly is very important. If the distribution box isn't working the right way you will soon be dealing with percolation field failure.

What is the difference between septic tank and distribution box?

The septic system works by sending wastewater from your home through pipes that take it to a septictank. From there, the wastewater goes through more pipes to the distribution box. This distribution box distributes the wastewater evenly through field lines into the percolation area.